Maintenance Services

Mechanical Services

Workshop or On-site Repairs, Maintenance and Tooling

Mechanical services are critical to ensuring the efficiency, safety, and reliability of your site. DIALOG Fitzroy can manage comprehensive repairs and machining onsite or in our machine shop, addressing unplanned breakdowns or routine wear and tear. Our expert team utilises advanced tools and techniques to restore machinery and equipment functionality efficiently, minimizing downtime. From piping systems to tanks, structural steel components, and rotating plant machinery, each aspect of maintenance is handled with precision, ensuring that your facility maintains peak performance.

- Shutdown Support & Tooling – Management, Planning, Trades, Bundle Pulling/Repairs, Column Repairs/Refit & Welding Inspectors

- Specialist Welding, Pressure Vessel, Heat Exchanger & Heavy Fabrication Services

- Approx 325 Carbon/Chrome Moly/Stainless

- Approx 20 Duplex procedures

- Welding Inspectors

- Heat Exchangers – Full life cycle heat exchanger solutions and tooling for both off-site and on-site services for retubing, plugging, expansion and testing.

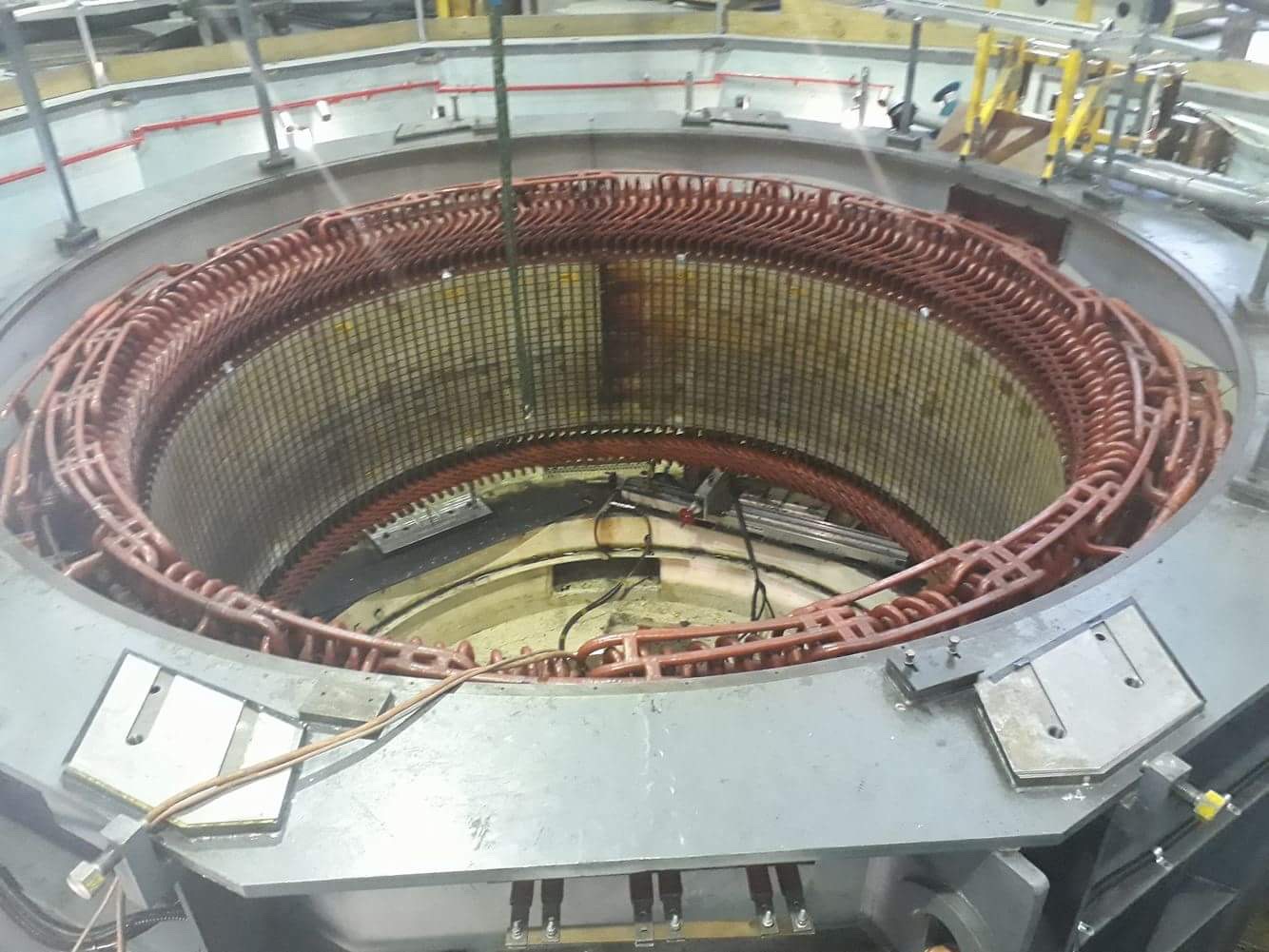

- Rotating Plant Services – Pumps, Fans, Turbines, Alignments

- Controlled bolting – hydraulic tensioning & torqueing, hydro testing, flange management and joint integrity solutions.

- Bolting and Tensioning

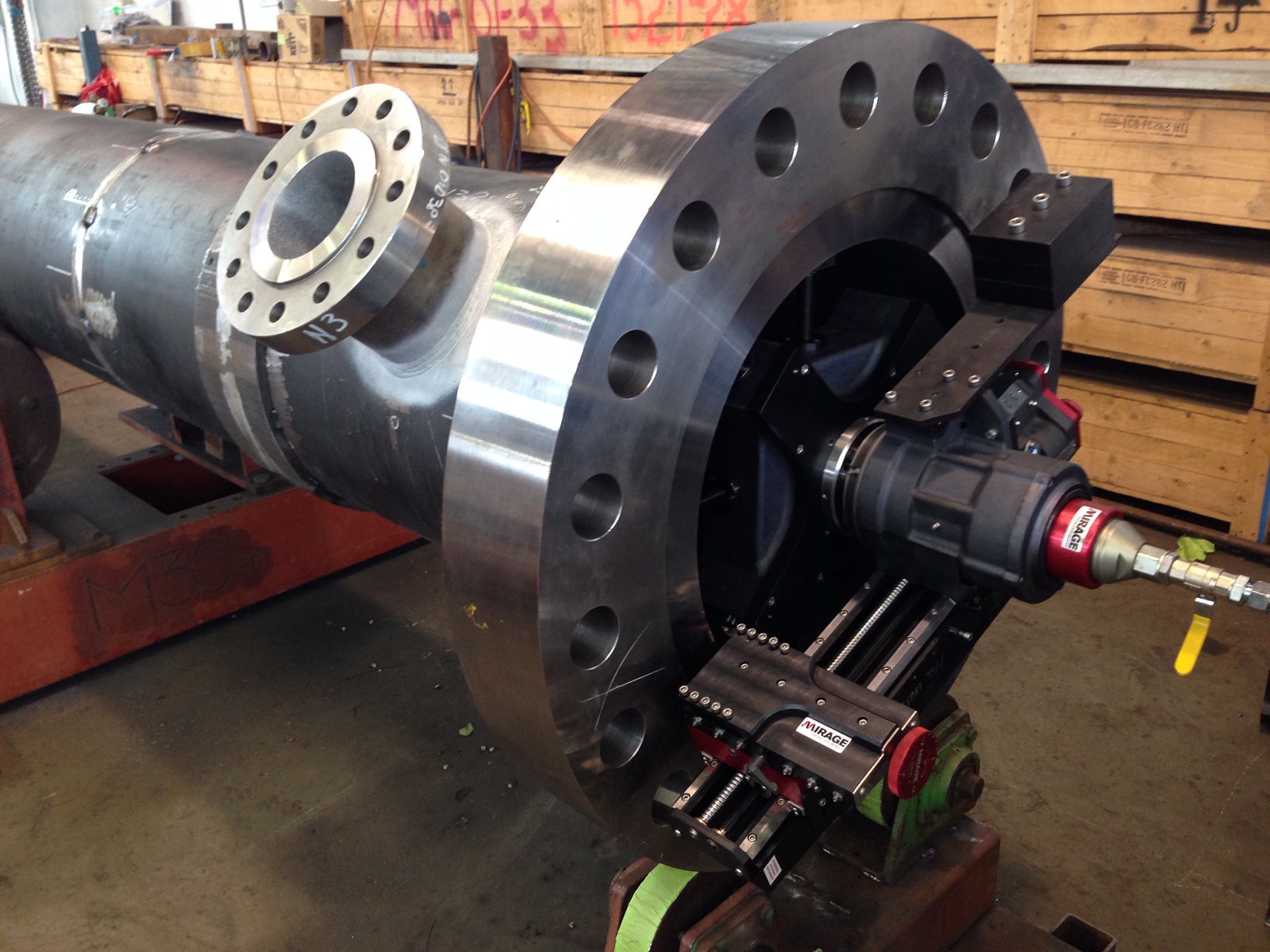

- On-site machining and cutting – Machinists for seal grooves, back facing, weld prep, counter boring, heat exchanger repair. Latest tooling technology from 0 -2000mm+ diameter. DIALOG Fitzroy have a portable 5 axis advanced robotic plasma cutter for heavy plate and pressure vessel precision cutting and In-Situ Pipe Cutting equipment for cold cutting from small to large bore piping. We also offer full workshop machining and CNC capability.

Get Started Today

Contact DIALOG Fitzroy

Reach out to us now to discuss your project needs and discover how our range of services can help.