OUR WORK

Tauhara Geothermal Power Station

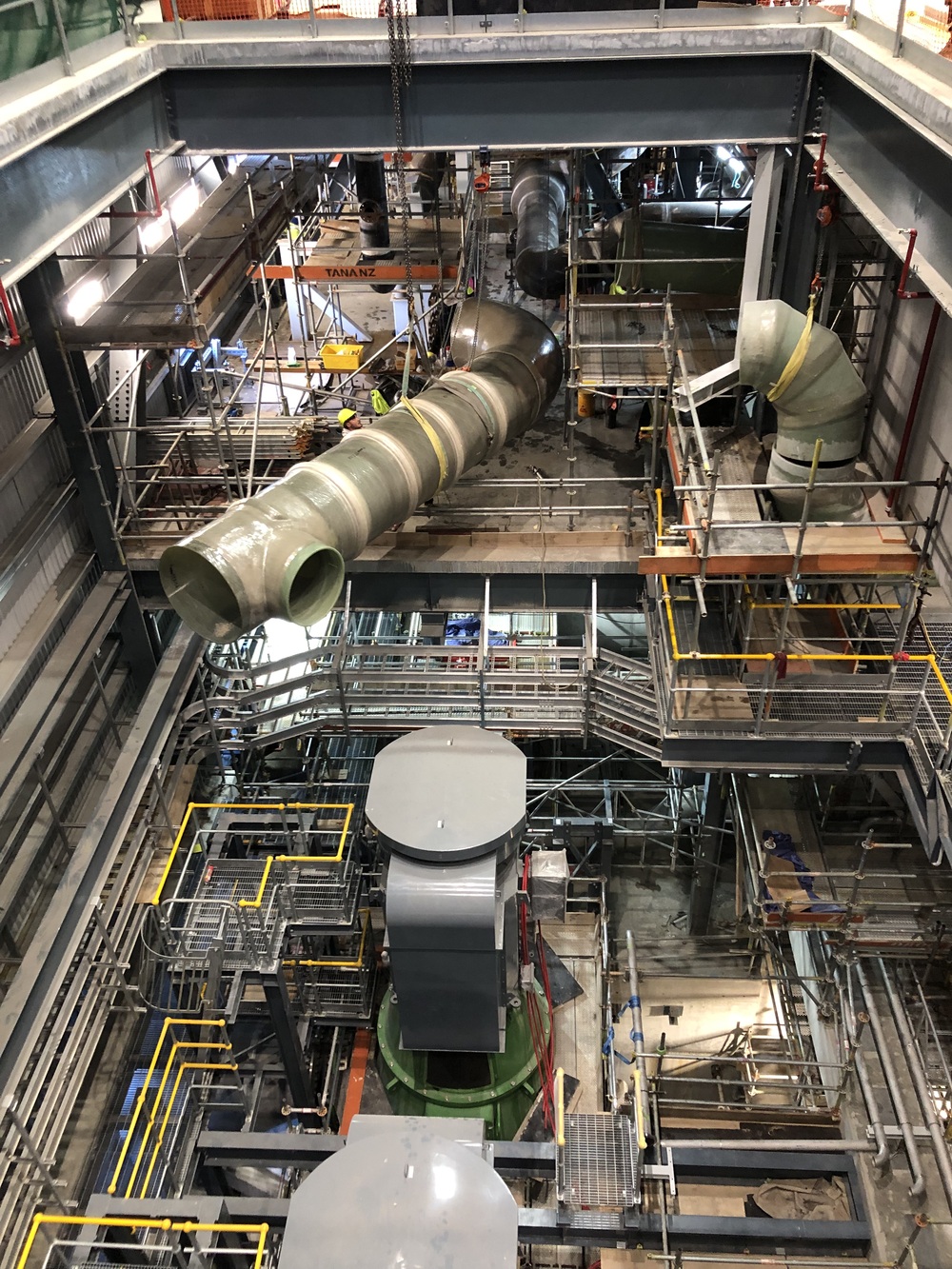

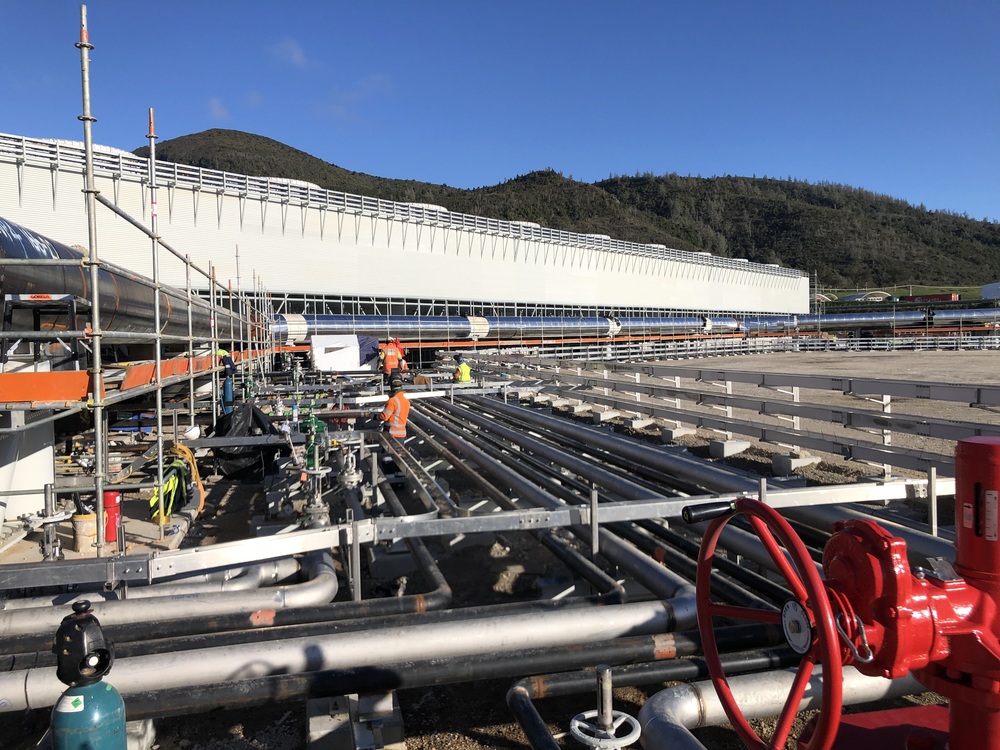

The Tauhara Geothermal Project involved the construction of a 174MW geothermal project station in Taupo, New Zealand, developed by Contact Energy and Tauhara Moana Trust.

DIALOG Fitzroy was engaged to deliver the lead mechanical supply and installation for Sumitomo and Contact Energy.

Project Requirements

Brownfield Site Demolition

- Live environment demolition works

- Confined space entry

- Working at heights

- Coordination of activities to maintain operations efficiency and safety protocols

Fabrication

- Pipe spooling

- Scrubber vessels

- Hot water suction header

Installation of Critical Components

- Steam Turbine

- Turbine auxiliaries

- Chemical treatment system

- Generators

- Colling Towers

- Piping systems

- Heat exchangers

- Scrubber vessels

- Free issue parts

Services Provided

Demolition/Removal of Mechanical Equipment including:

- Decommissioning and removal of existing large bore pipework

Pipe fabrication and installation including:

- Spooling and installation of free issue Carbon and Stainless Large/Small bore piping for water lines, including cooling and process water systems, control oil piping, Instrument Air piping, gland steam, compressed air, GES (Gas extraction system) and ejector piping.

- Installation of underground and above ground FRP large bore piping to Cooling tower.

- Fabrication and installation of the Ceco Scrubber Vessels and connections.

- The piping systems for transporting water from the geothermal reservoir to the power station and vice versa.

- Installation of low-pressure gas piping

- Coded pipe welding covering a range from 15 nominal bore to 1250 mm, utilising materials such as stainless steel, carbon steel, and low-temperature carbon steel.

- Integration of piping systems with other mechanical components to ensure efficient operation of the geothermal power station

Installation of critical components including:

- Steam turbine generator supplied by Fuji Electric – the world’s biggest single-turbine geothermal power unit at 174 MW

- Hotwell pumps to main cooling system

- Chemical treatment system

- Installation of Condensers x 2 including methodology changes once they arrived in NZL.

- Installation of generators

- Fabrication and installation of 3500NB Hot water suction header.

- Installation of induced draft cooling towers risers only and associated infrastructure.

- Fabrication and installation of piping systems for transporting water between the geothermal reservoir and the power station.

- Installation of heat exchangers for transferring heat between water and steam or air, along with various mechanical components such as valves, fittings, and gaskets.

Get Started Today

Contact DIALOG Fitzroy

Reach out to us now to discuss your project needs and discover how our range of services can help.